Single Gauge Introduction: Our Uncompromising Quality, Customer Oriented Services and Competitive Prices have made our Gauges very popular in the Indian Engineering Industry.

Project 1 :

Description :

Parameters Checked :

Features :

Bench mounted I.D. gauge

Description :

- Bench mounted Internal Diameter ID checking gauge with Direct/Automatic Relay connection to Marking machine

Parameters Checked :

- Internal Diameter

- Ovality

Features :

- Very fast inspection rate.

- Integrated into Marking making machine for instant size etching.

Project 2 :

Description :

Parameters Checked :

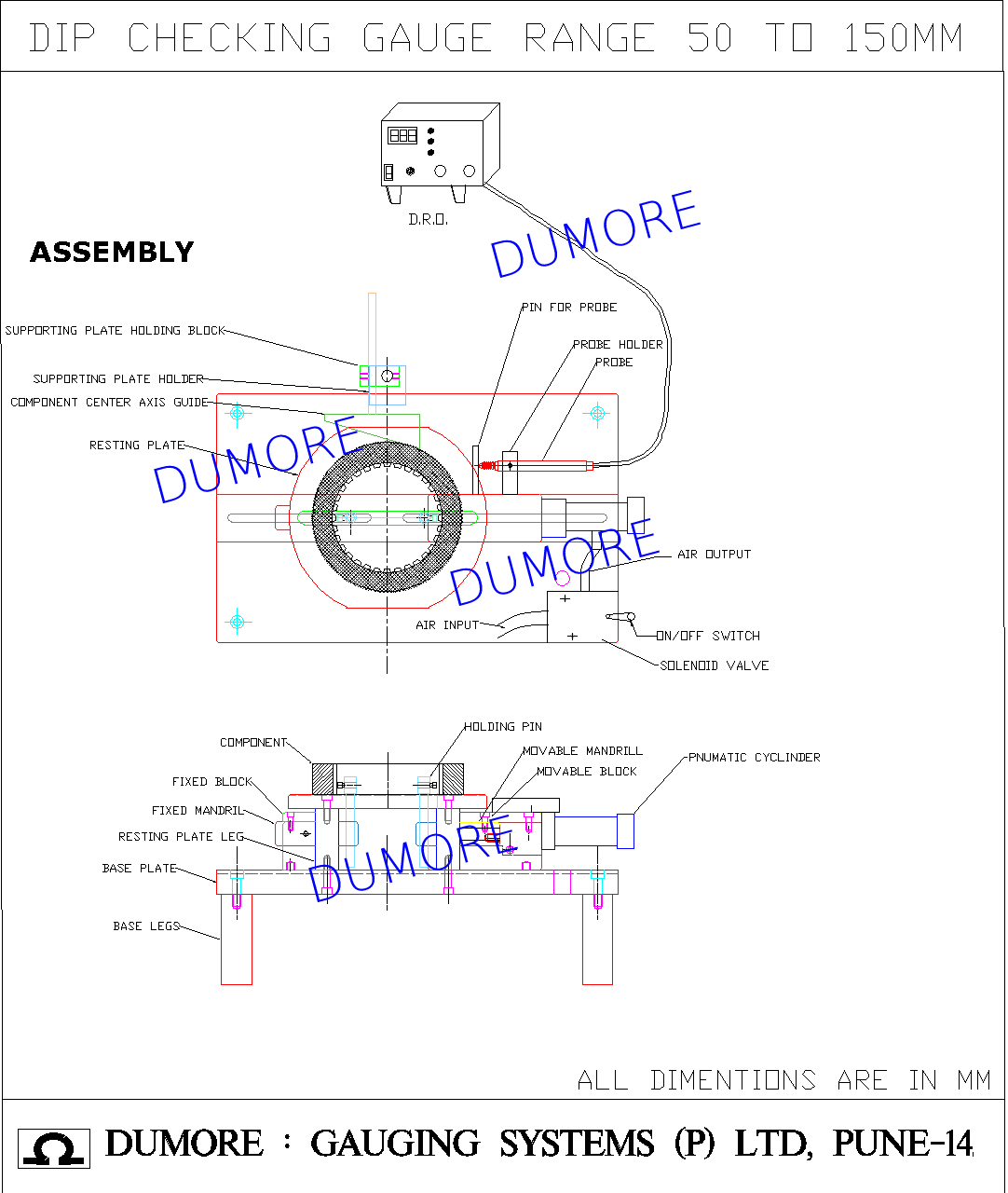

Features of Special DOP & DIP Checking Gauges :

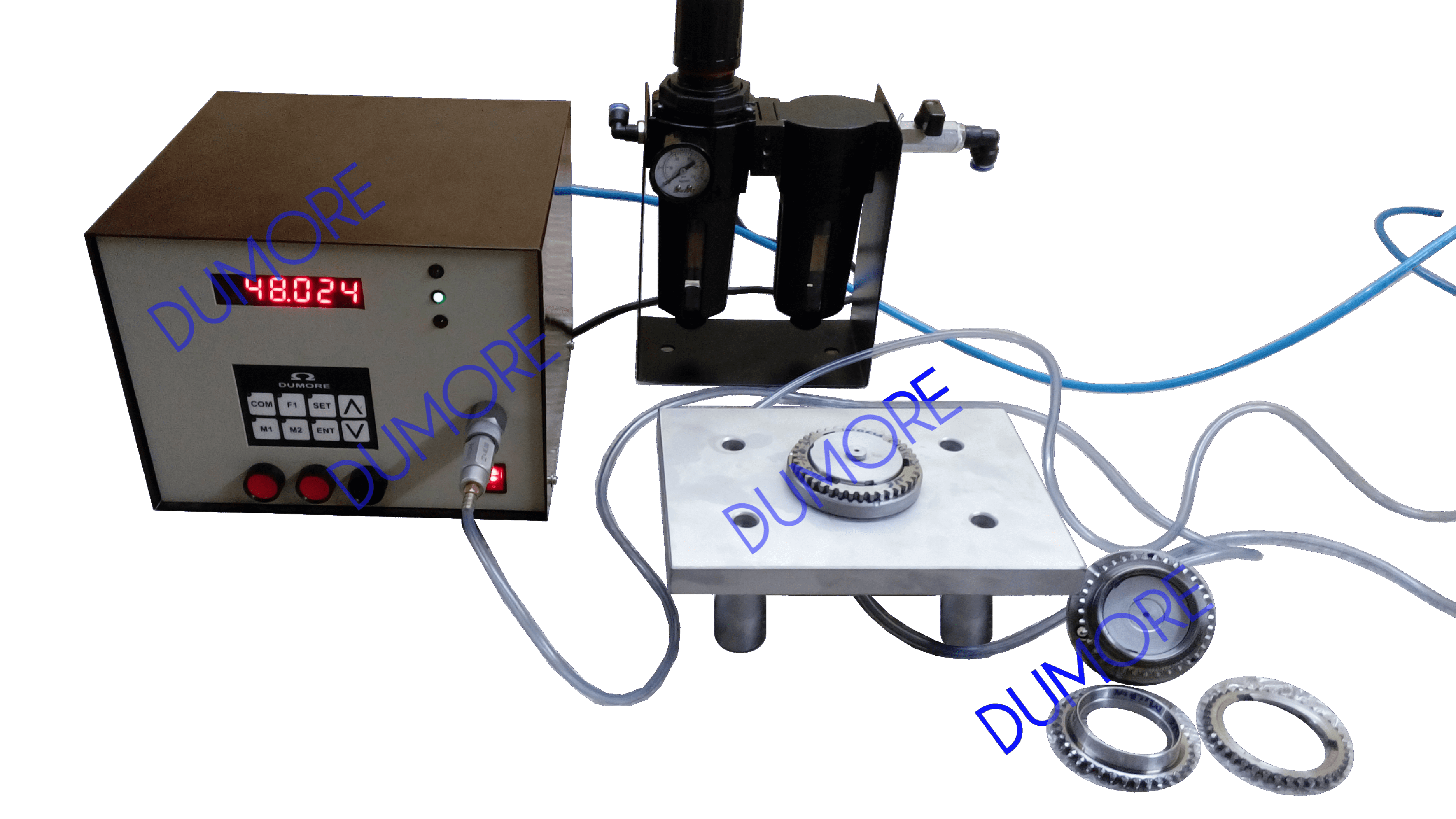

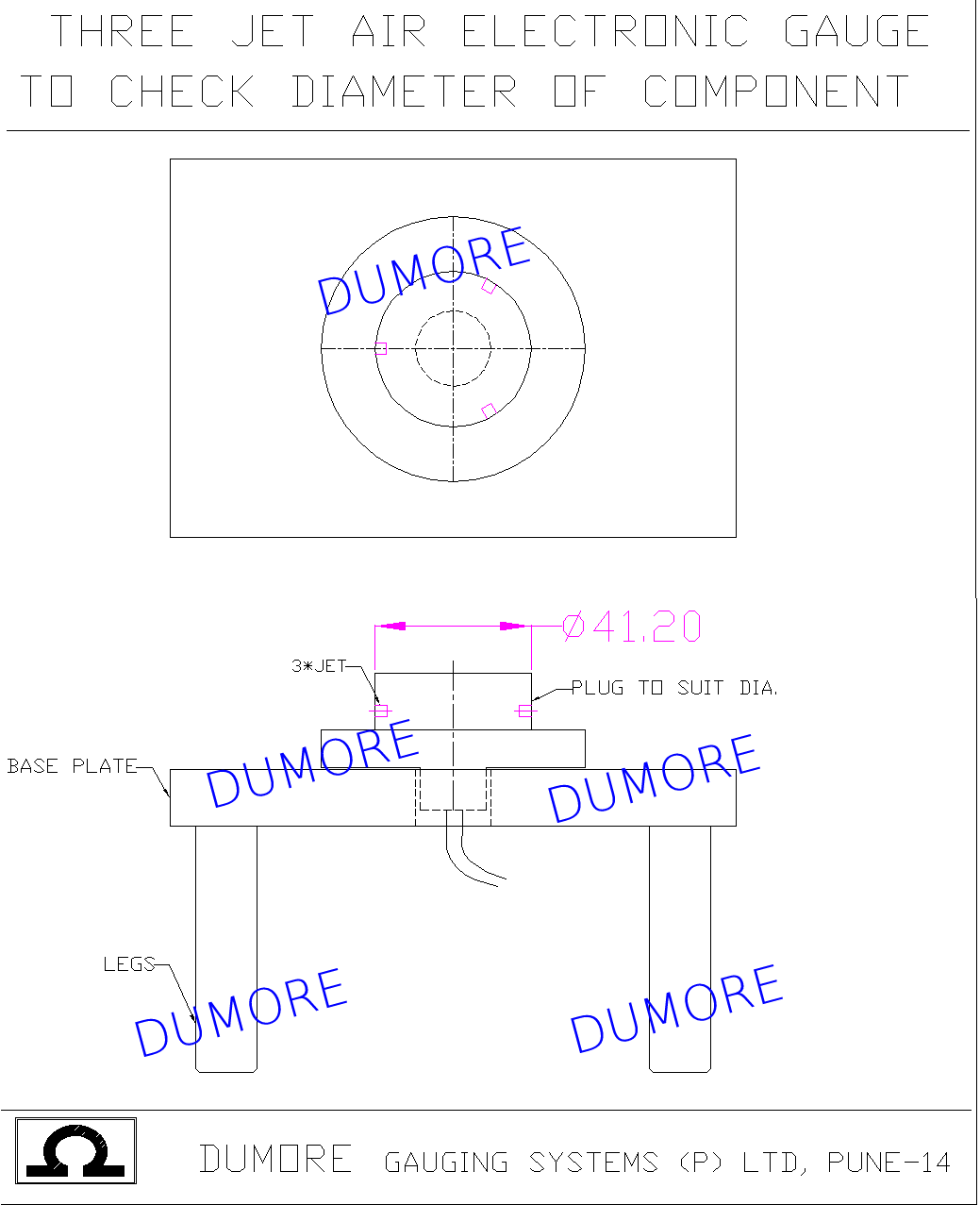

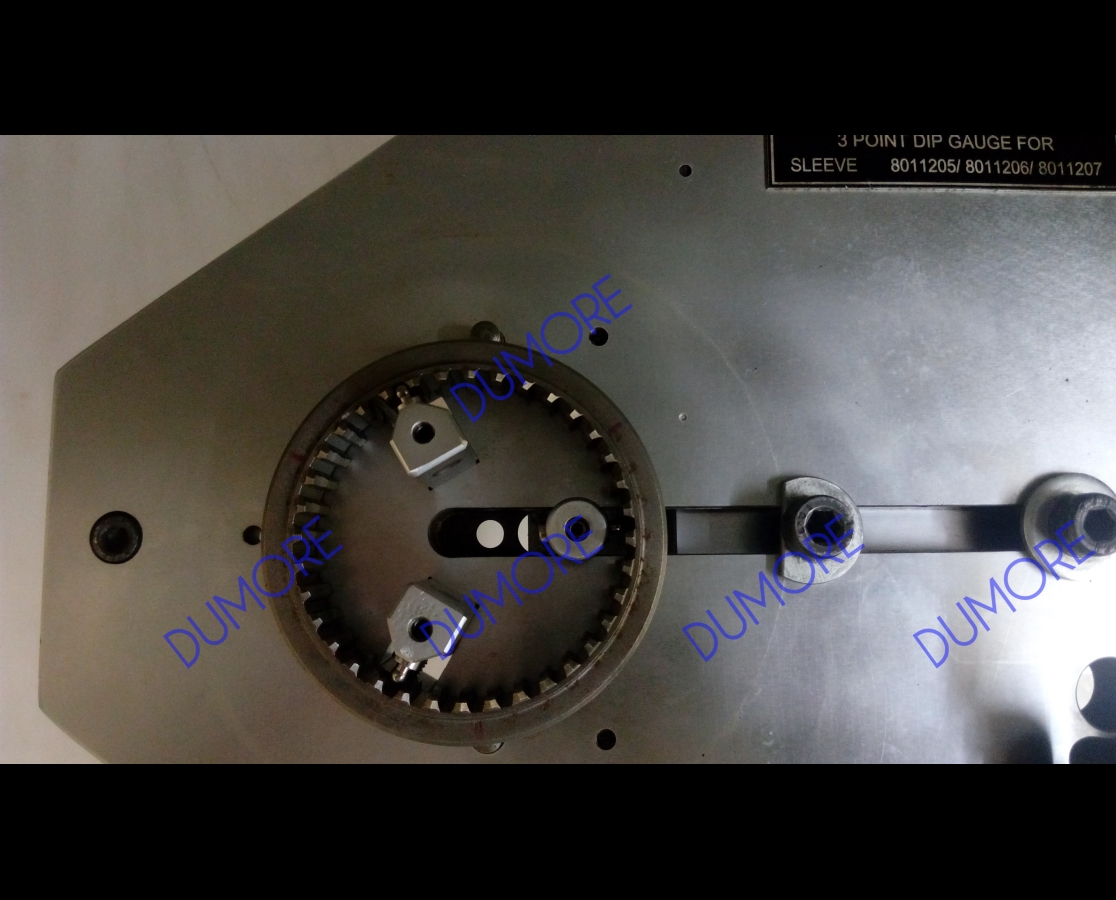

Internal Gear Teeth DIP

Description :

- Gauge for I.D. with Special 3 Point Contact and Pneumatic controls for operator ease.

- This gauge is normally always made with 2 point contact.

Parameters Checked :

- Diameter Over Pin DOP or

- Measurement Over Pin MOP or

- Over Ball Diameter OBD

Features of Special DOP & DIP Checking Gauges :

- Adjustable Range for DIP 40-150mm, 150-250mm

- Very fast and convenient method of inspection

- Both odd and even no of teeth gear DOP/DIP can be checked

- Provided along with standard size ball anvil sets

- DRO and probe or Dial Gauge as readout option L.C.= 0.00 1mm

- Adjustable base, DOP/DIP can be checked at different heights

Project 3 :

Description :

Parameters Checked :

Features :

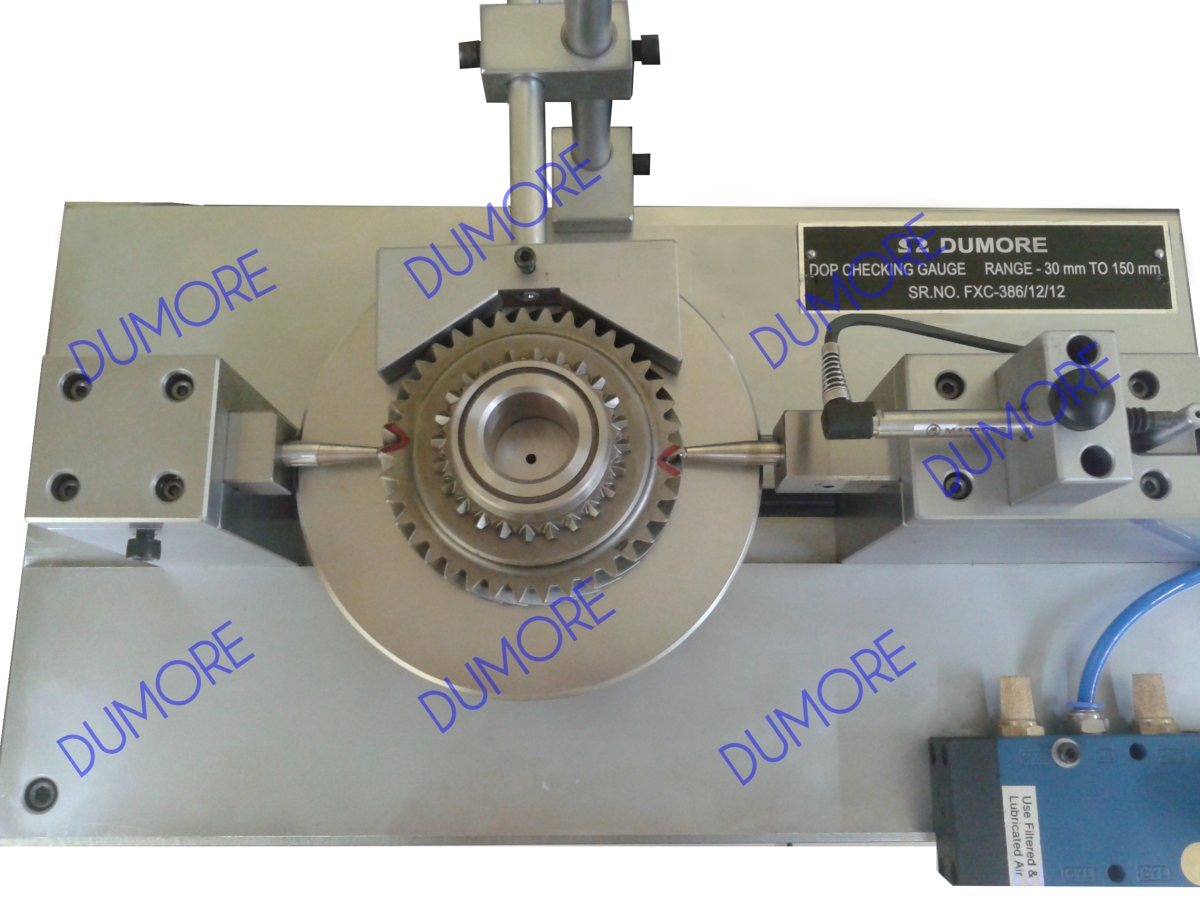

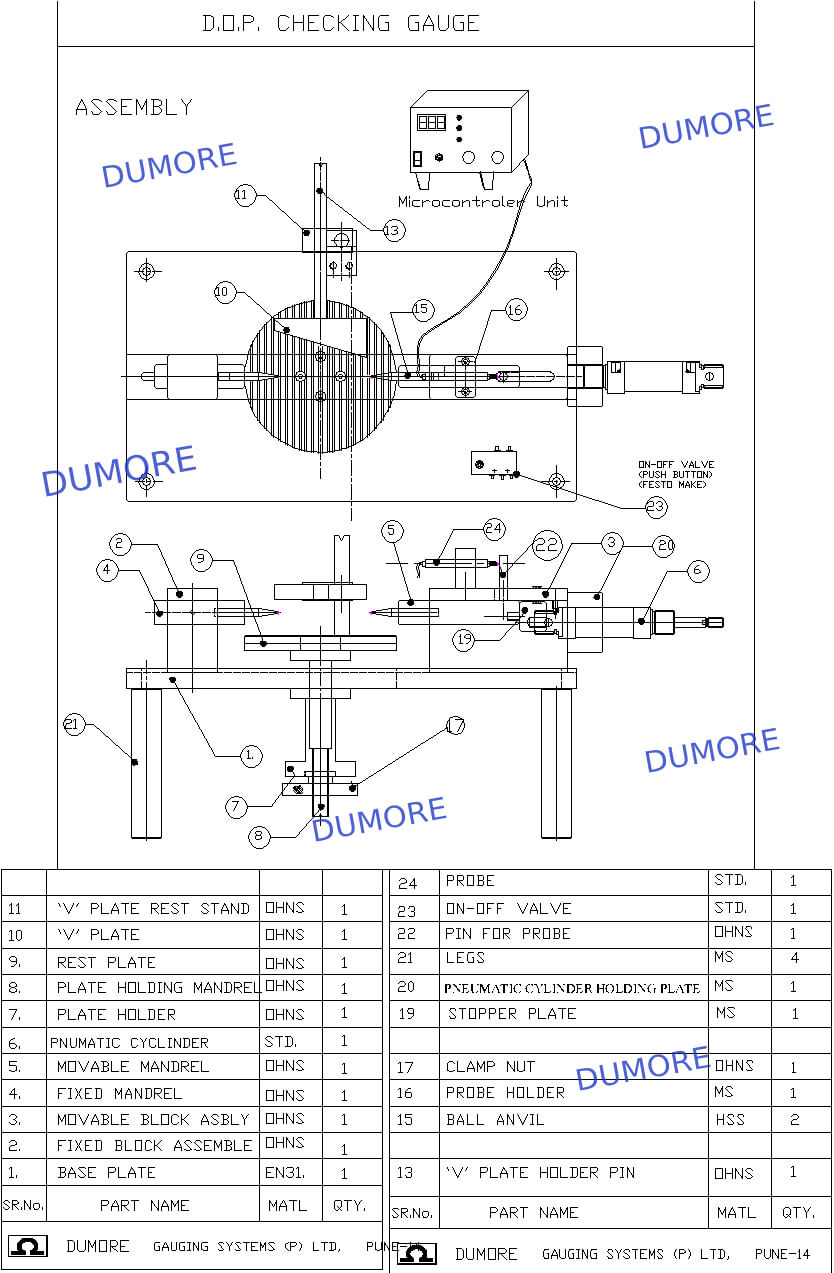

Diameter Over Pin gauge (DOP / MOP / OBD)

Description :

- Dumore Universal Gear Check Gauges (D.O.P. Checking Gauge) is used to check DIAMETER OVER PIN of Gear Component for Gear/Spline with Pneumatic controls for operator ease.

Parameters Checked :

- Diameter Over Pin DOP or

- Measurement Over Pin MOP or

- Over Ball Diameter OBD

Features :

- Adjusted range: 50 to150mm, and 150mm to 300

- Least count : 0.001mm

- Repeatability : +/- 0.001mm

- Reading can be displayed on the dial gauge

- The run out of D.O.P. also can be measured by rotating the gears

- An adjustable V-rest enable the operator for easy checking

- Odd & Even no. of teeth can be checked with this system

Project 4 :

Description :

Parameters Checked :

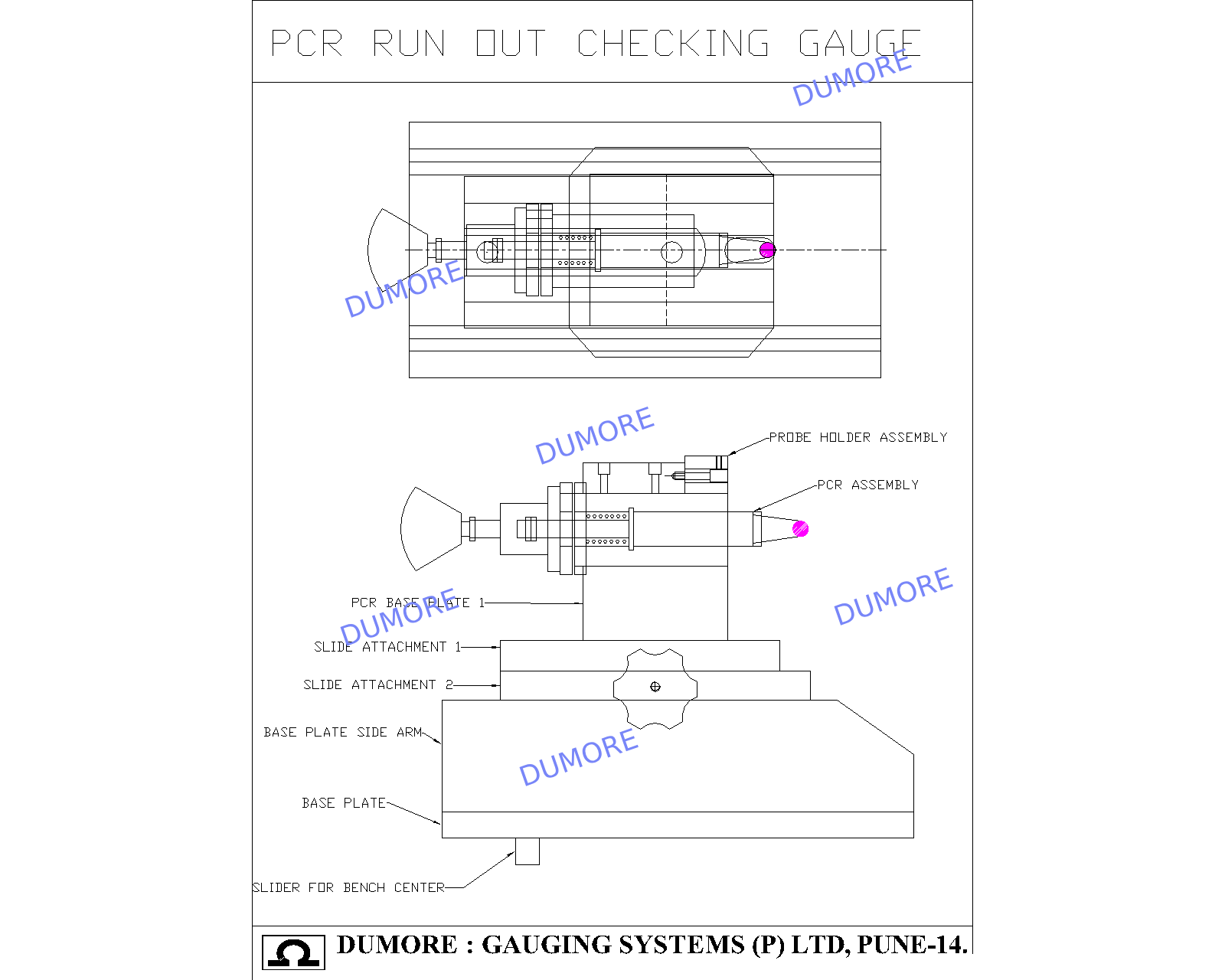

PCR/PCD Checking Gauge

Description :

- This Dumore Gauge is used to check PITCH CIRCLE RADIUS of teeth on Shaft Spline.

- The component needs to be held between centre on your Bench centre. Our gauge can move in the X-Y axis easily.

- Please Note-Dial Gauge can be replaced with LVDT sensor for connection of Electronic Display Unit and also SPC/SQC Software.

Parameters Checked :

- PCR - Pitch Circle Radius

- Spline Radius Over Ball from Central Axis

- Spline dia. RunOut/T.I.R. gauge

Project 5 :

Description :

Uses :

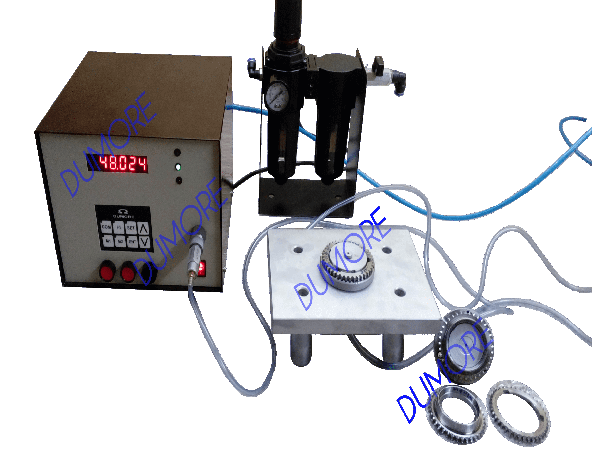

Plug Gauge Sets

Description :

- These Air Plug Gauges are made from very high quality raw material which ensures hassle free work performance at its user end. Air Plug Gauges widely finds its applications in various industrial sectors.

- Various sizes of plug gauges for many diameters along with their respective High-Low Masters and Air Gauge units(Display units) – as shown in photo below.

Uses :

- These gauges can also be added to digital display systems.

- Differential ID checking plug gauge - Handheld Plug Gauge with special arrangement for supporting Differential component.

Project 6 :

Description :

Applications of Air Calliper Gauges :

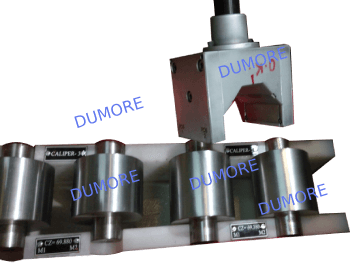

Air Calliper/Snap Gauges

Description :

- We are one of the reputed organization engaged in providing superior quality Air Calliper Gauge. These Gauges are good demand in the market due to high quality and durability & are available in market at competitive rates.

Applications of Air Calliper Gauges :

- To check outer diameter, taper and ovality of specified size for different types of components (shafts): middle jet, corner jet.